Research & development in the field of green technology

Precision from the very beginning

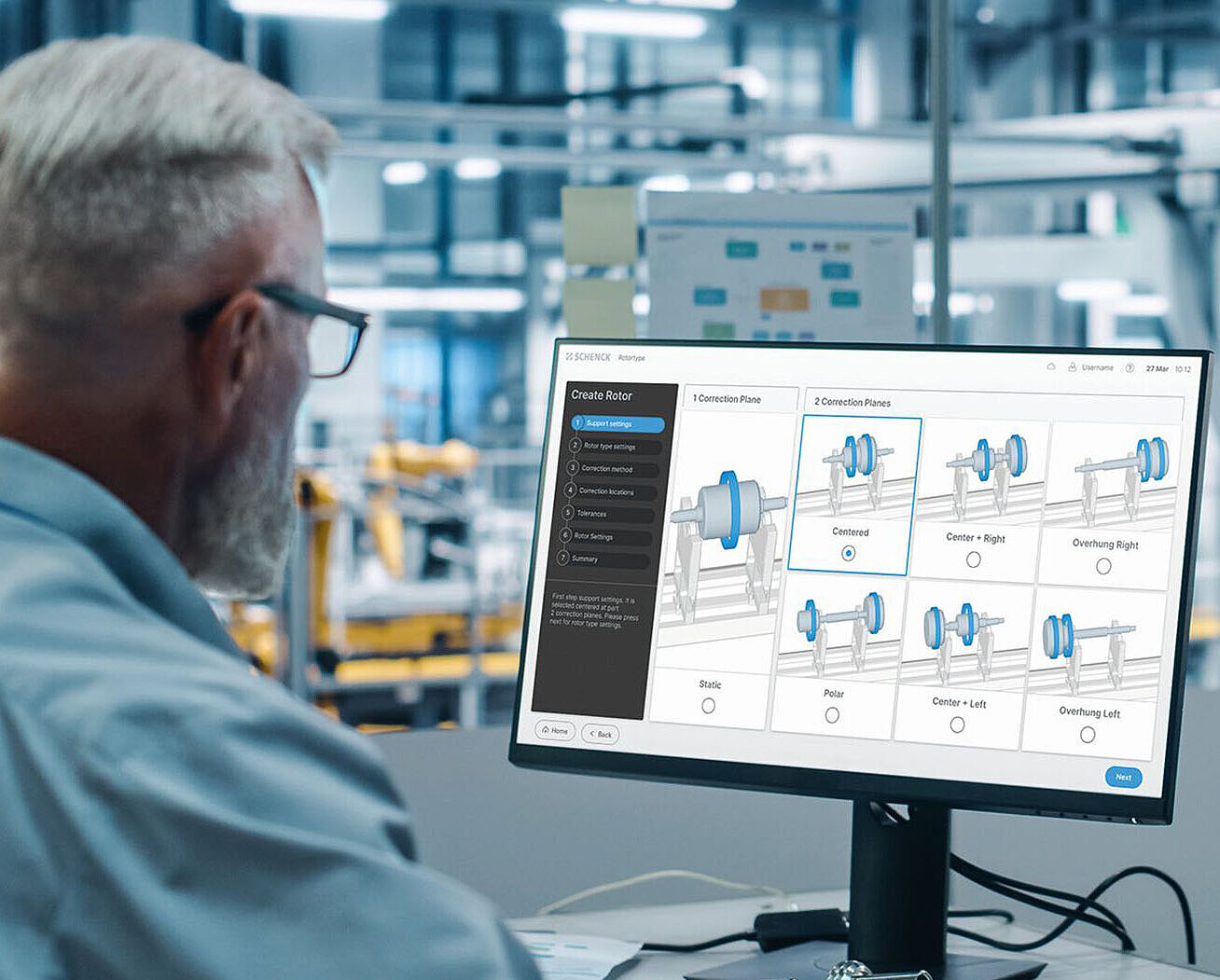

The design and development phase of a new product is crucial for its success on the market. The first step in a development process determines how vibration-free your rotor will run in series production. It is important to keep an eye on the unbalance of the prototype and to take appropriate measures. We can provide support at a very early stage with our imbalance budget. As soon as the first prototypes are available, we can spin them and simulate later environmental conditions. This enables us to examine the limits of the prototype in terms of centrifugal force. In addition, we can further analyze the finished prototype, measure vibrations and calculate suitable balancing strategies with various other consulting services in the field of unbalance.

Your advantages with professional consulting in the field of spin service and unbalance analysis

Our services for you: unbalance budget, prototype testing, spin testing, process optimization & quality assurance

Early detection

of weak points

Quality

assurance

Optimization of

resources

Strength test

at overspeed

Service life tests

Avoiding cost-intensive

rework

Planning

security

Quality control

of production

Do you have any questions regarding your rotor?

We are happy to advise you and support you in the development and testing of your rotor.

We support you throughout your development process

Planning & Construction

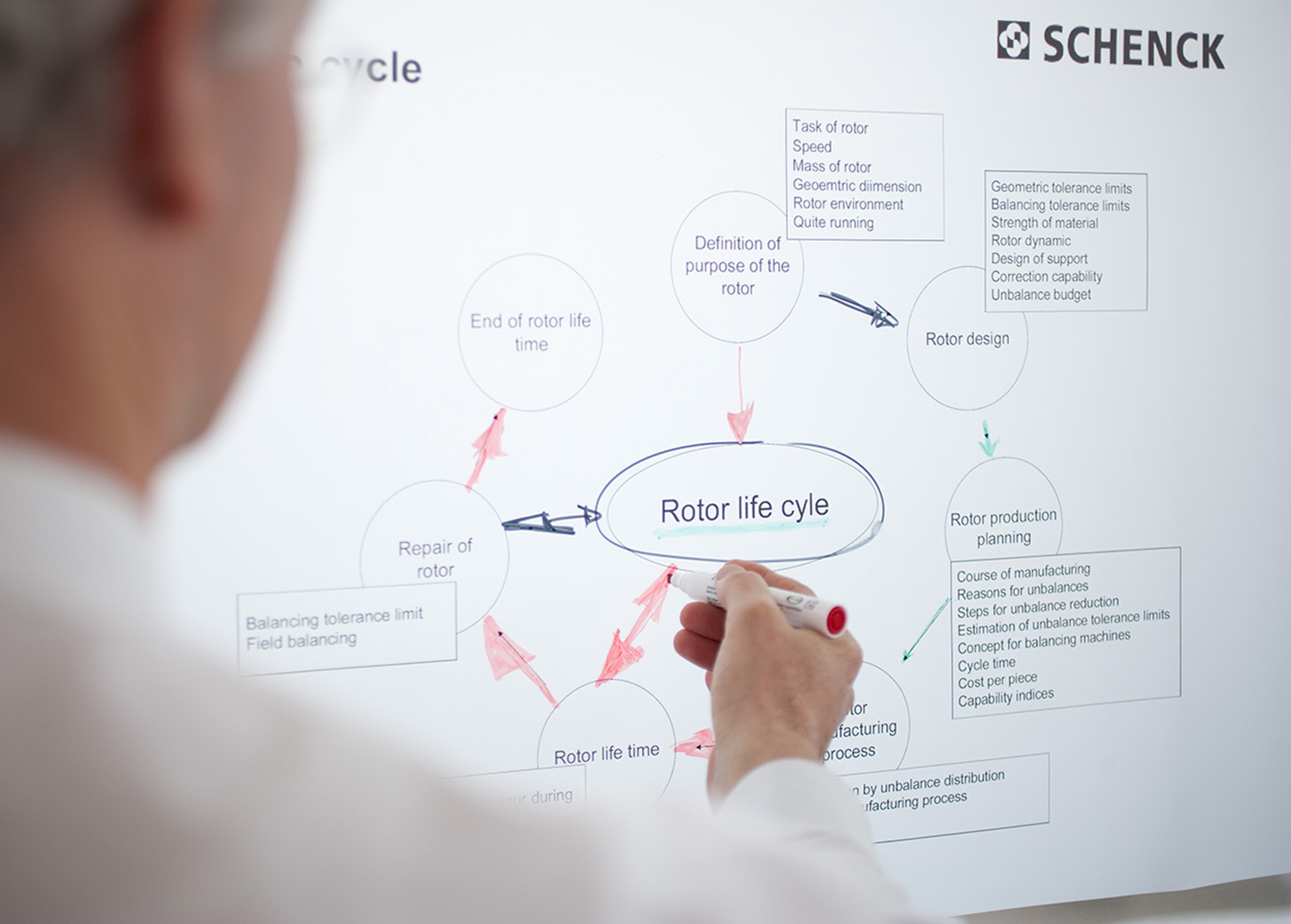

Aprecision is the key to success. The way in which rotors run with low vibration is decided as early as the product planning stage. That is why you benefit from involving our experts in the development process from the outset. With in-depth know-how and special technologies, we analyze influences on the subsequent vibration and noise behavior. We can provide initial estimates regarding the expected unbalance based on drawings alone – and thus minimize it as early as the development stage. Your added value: components that can be stabilized much more efficiently in terms of vibration during the manufacturing process.

Prototyping & Testing

As soon as a component is available as a prototype, its weak points become evident. In our test site, we analyze rotors and aggregates and calculate their behavior in actual operation. For rotors that have to withstand high centrifugal forces, we offer a spin test service for strength and expansion tests up to 250,000 rpm, as well as burst tests regarding operational safety. We also carry out all the necessary work on your test specimens for new and further developments or as part of quality assurance.

Production & Optimization

As a manufacturer of balancing solutions, we focus on making production processes more efficient. We understand how much potential for reducing costs lies in the production process. That is why we analyze your production solution in detail, ask the right questions and optimize the process in order to integrate it intelligently into your production. This allows you to manufacture high-quality products while implementing efficient solutions.

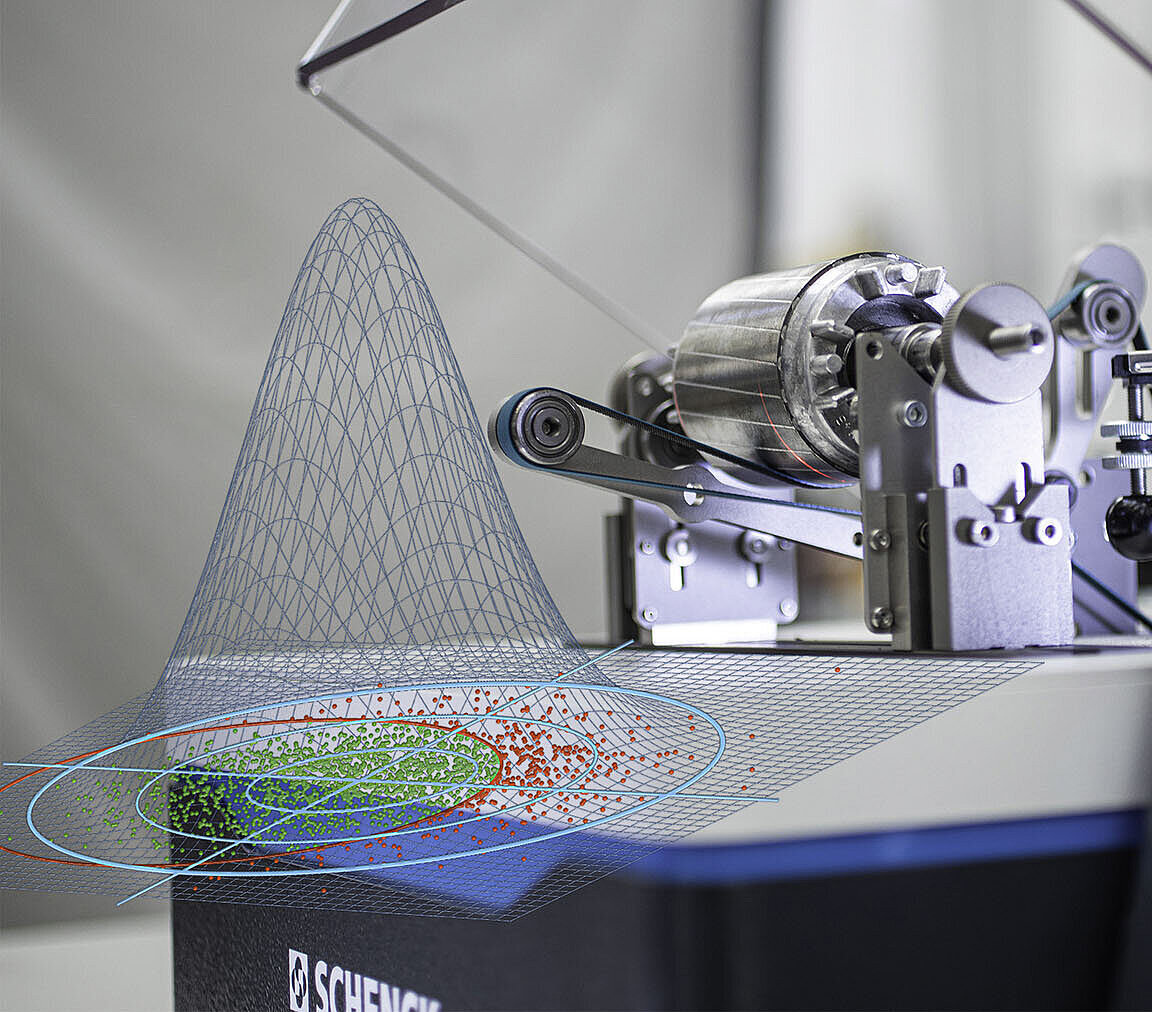

A wide range of parameters documents the quality of the process and the components. By continuously collecting data, you can prove the quality of your products to your customers and at the same time create the basis for continuous process improvements. Our software helps you to calculate even complex quality parameters and use them for your workflow.

Balancing budget

Low-vibration products right from the beginning

At the development stage of a rotor, knowledge concerning the likely imbalance distribution in the subsequent production is not available. All of the construction elements of the rotor, with their geometric tolerance specifications, contribute to this unknown distribution. A budget of the original imbalance of the new, not yet completed rotor is obtained by listing each imbalance contribution in the form of a likely distribution. The aim of the unbalance budget is to analyze the devlopment of unbalance in a rotor at an early stage of its development in order to possibly adjust the manufacturing tolerances and determine the correct balancing strategy. This provides the opportunity to test whether the planned imbalance correction has the correct scale. Since this can take place at an early stage of development, you are protected from expensive surprises.

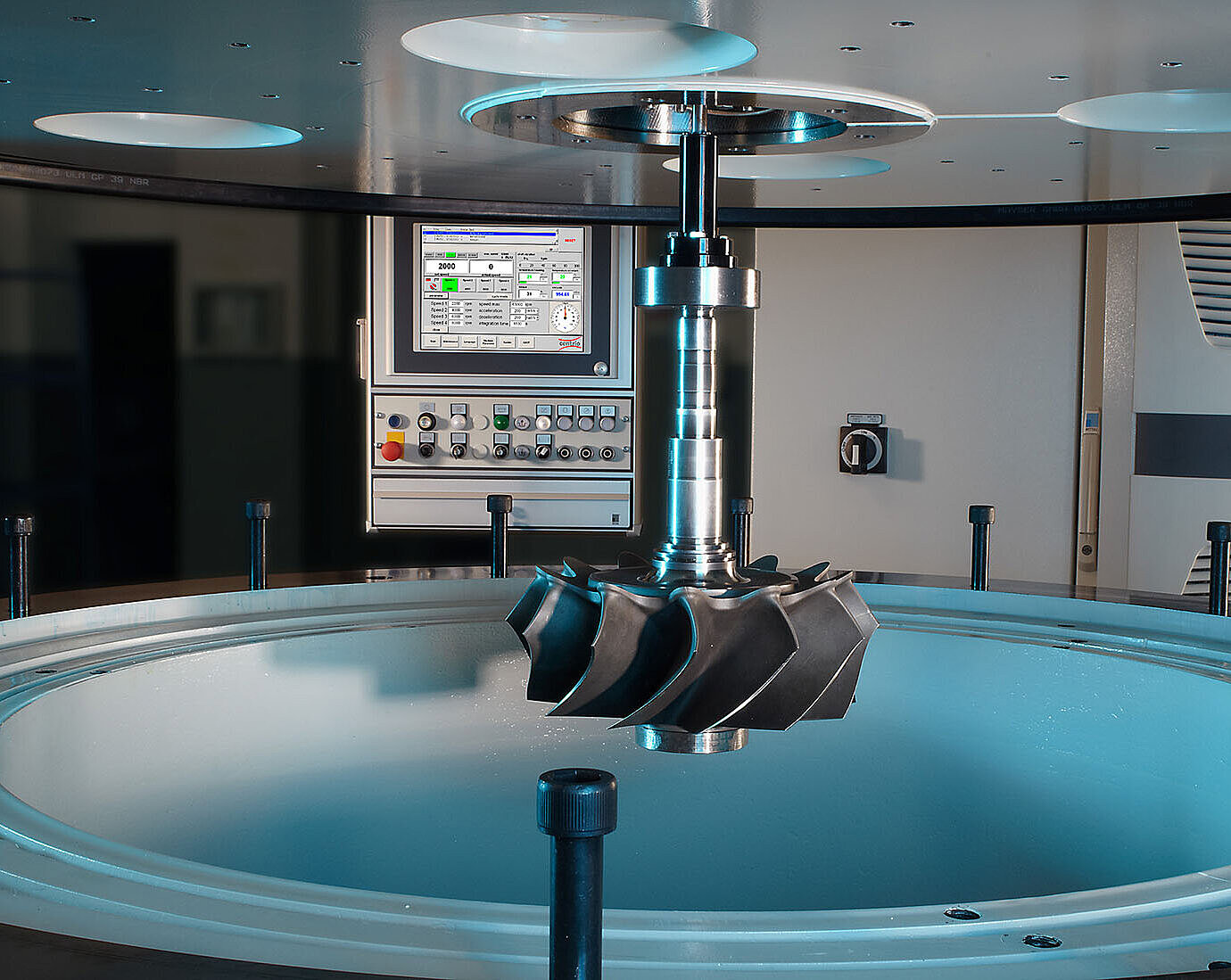

Unbalance analysis of prototypes

Your sure path into production

A component's real characteristics only become apparent once it has been built as a prototype. In our test site, we analyze rotors and aggregates and calculate precisely how they will perform in actual operation. Our vibration test supplies you with the knowledge you need for further design engineering to better undestand your rotors. After that, our spin test service is the ideal way to carry out strength and expansion tests in the speed range up to 250,000 rpm or to ensure operational safety with burst tests. And if you wish, we can support you with suggestions on how to improve your product as a whole.

Schenck Training

In our training courses and workshops, we specifically address your challenges and individual requirements.

Spinning service

Your sure path into production

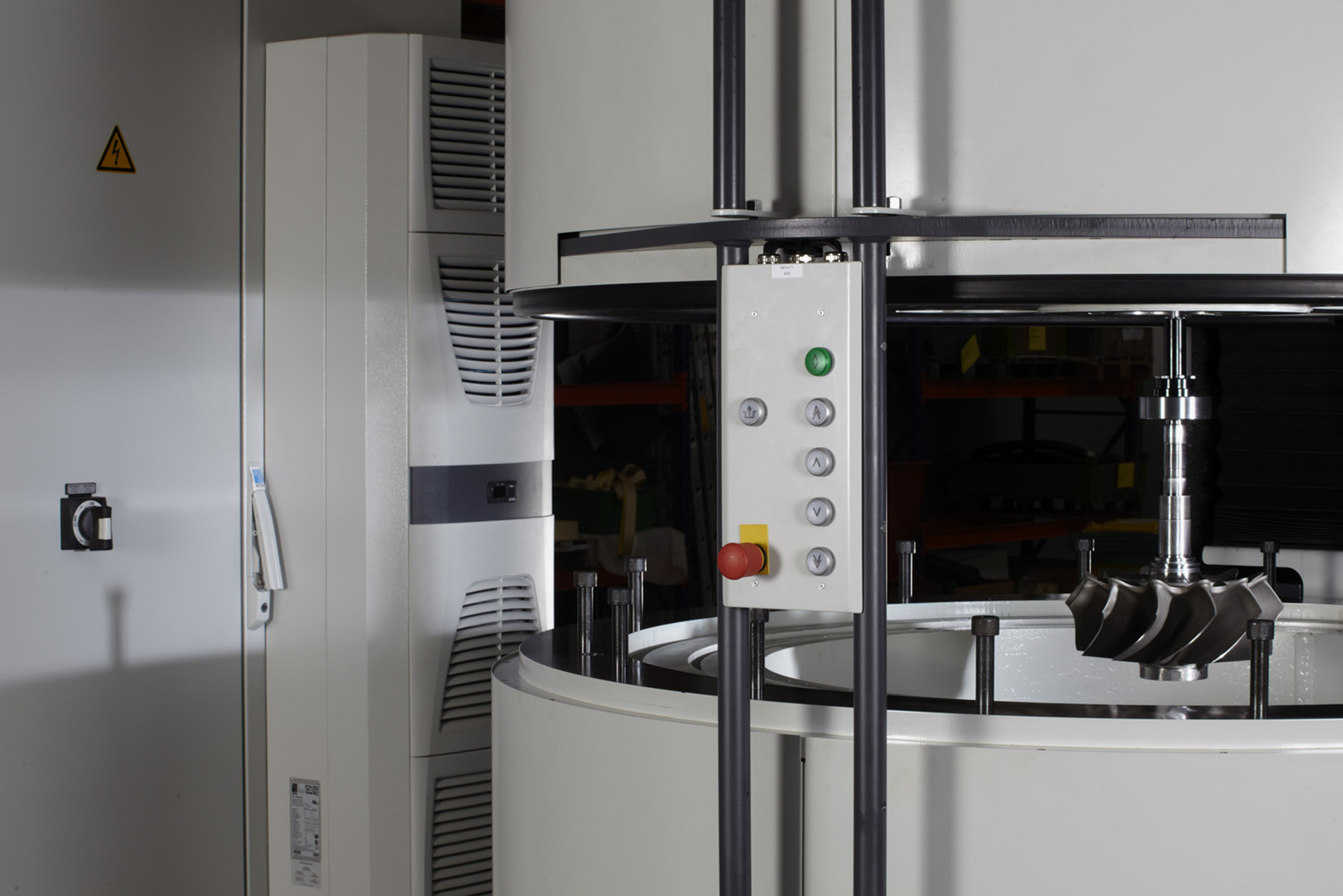

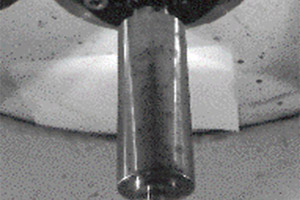

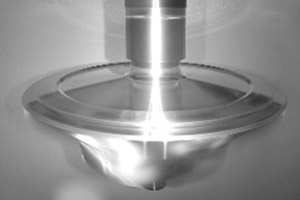

If rotors are subject to high centrifugal forces during operation, you need to be sure that they will not become permanently deformed or burst over time. Proven methods include strength tests at speeds above the operating speed, burst tests or the performance of service life tests using cycle tests. This gives you the certainty you need to operate your rotors. We carry out a variety of necessary tests on your rotating components for new and further developments or as part of quality assurance.

Our spin-testing service for your prototypes

We offer our customers a wide range of services in the field of spin testing, depending on your rotor and your area of application. In our Green Technology Center, we can use the latest technology to offer you innovative analysis options.

Spin Testing:

- Pre-Spinning

- Overspeed tests

- Cycle tests

- Burst tests

Performance data:

- up to 400kg rotor mass

- up to 250.000 rpm

- up to 1000mm rotor diameter

Tooling:

- Customized design and construction

- Manufacturing

Rotor heating:

- up to 250° Celsius

- higher temperatures on request

- flexible solution, also suitable for burst tests

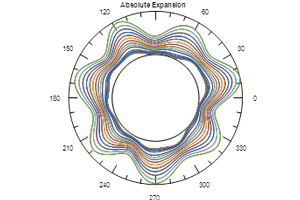

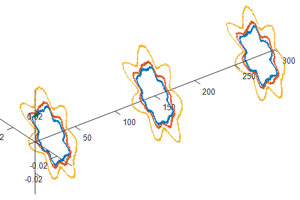

Dynamic expansion measurement:

- 360-degree analysis of individual rotor levels

- Analysis of elastic and plastic behavior

Rotor Burst with High-Speed camera:

- Highspeed-Video during burst tests

Visual Inspection & High-definition video:

- High resolution visual inspections at standstill or during the spin cycle

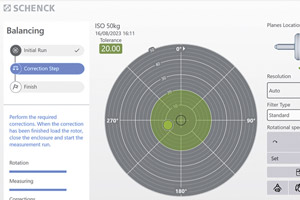

Unbalance analysis:

- Measurement of the unbalance condition before and after spinning

- Detailed analysis of the changes

- Cause allocation in the rotor design

Plastic deformation analysis:

- Comparative measurement of the geometry before and after the centrifuging process

- Detailed analysis of the plastic deformation

Schenck Green Technology Center

The Schenck Green Technology Center combines our many years of experience with state-of-the-art technology - for faster product development and quality processes under TISAX® standards.

Process optimization & quality assurance

It´s all about your profitability

To keep things running smoothly. As a manufacturer of balancing solutions, our business is the design of efficient production processes. We know how much potential lies in reducing costs of balancing processes. This applies in particular to complex products. We analyze your balancing solution in detail and ask the right questions. We optimize the balancing process and integrate it intelligently into your production. In doing so, we help you establish the optimum relationship between high-quality products and efficient solutions.

Quality needs to be assured. Can you confirm the quality of your processes at any time? Various performance indicators are used to document the quality of processes and components. If this data is collected continuously, you can confirm the quality of your products to your customers. At the same time, you create the basis for continuous process improvement. The experts at Schenck RoTec can help you calculate even complex quality indicators – and prepare them for use in your workflow.

Our holistic approach

We offer our customers comprehensive support throughout the entire process. From consulting and planning to measurement and testing, we are by your side to ensure that your needs are met comprehensively and effectively.

Testing & Measuring

Make sure that your own balancing and spin testing system meets the required standards. We can help you with this – with a range of customized service packages.

Solutions & Products

From spin stands to balancing machines for rotors in series production. Our Green Technology product portfolio covers the entire process chain.

Green Technology Center

Our new Green Technology Center bundles the spin- testing and validation services of our testing laboratory and consulting division. Benefit from this unique ecosystem.