Green Technology Center

Enabling sustainable rotating technology

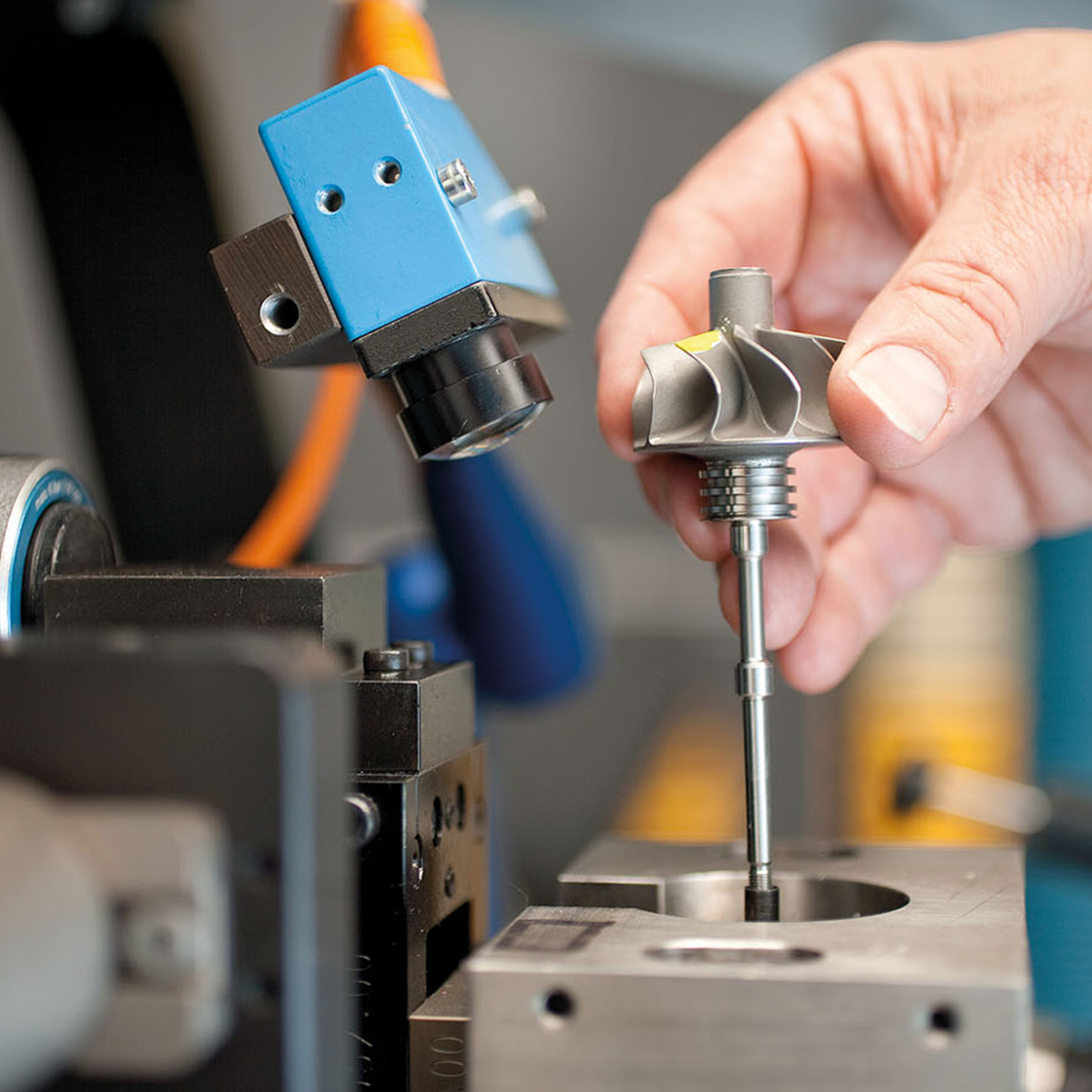

The constant growth in the field of e-mobility requires continuous innovation in engine technology, especially in the production of new, efficient rotors. Schenck RoTec's Technical Consulting supports manufacturers in testing their rotors with shear tests – now in the newly opened Green Technology Center.

The bundling of testing facilities in the Green Technology Center leads to improved product quality and shorter development cycles.

From design to production of sustainable rotors

Do you have questions regarding your rotor?

We are happy to advise you and support you in the development and testing of your rotor.

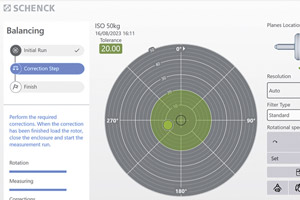

Your main ecosystem for suitable solutions in the field of green technology

The Green Technology Center is equipped with four different spin test stands. Each stand is mounted on its own foundation, which ensures a high level of accuracy in the tests. After the spin tests, the rotors are examined in a specially equipped measuring room that has three high-precision coordinate measuring machines. In front of this is a tempering room in which the rotors can be brought to the temperatures required for the measurement. The center also has four balancing machines, two Pasio 50s and two Pasio 15s, to correct any imbalances that may occur on the spot.

Innovative spin and validation services at the new Green Technology Center

As the market leader in the field of balancing technology, it is an essential part of our strategy to allow sustainable innovations in the technical market environment. In the future, our new Green Technology Center will therefore bundle our spin and validation services. Our many years of experience in balancing and vibration analysis, coupled with the latest technology, will significantly accelerate our customers' product development and quality processes in the field of sustainable growth markets.

Overview of the various services offered by the center

We offer our customers a wide range of services at the Green Technology Center, depending on the rotor and application. In our Green Technology Center, we can use the latest technology to offer you innovative analysis options.

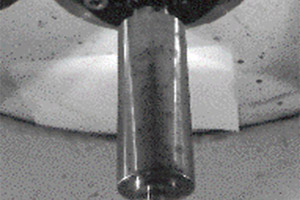

Our spin-testing service for your prototypes

We offer our customers a wide range of services in the field of spin testing, depending on your rotor and your area of application. In our Green Technology Center, we can use the latest technology to offer you innovative analysis options.

Spin Testing:

- Pre-Spinning

- Overspeed tests

- Cycle tests

- Burst tests

Performance data:

- up to 400kg rotor mass

- up to 250.000 rpm

- up to 1000mm rotor diameter

Tooling:

- Customized design and construction

- Manufacturing

Rotor heating:

- up to 250° Celsius

- higher temperatures on request

- flexible solution, also suitable for burst tests

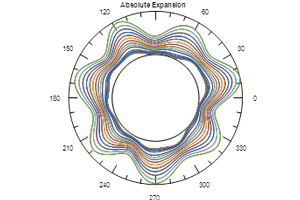

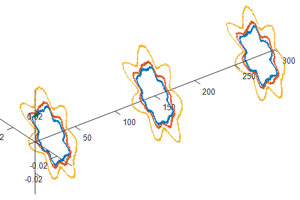

Dynamic expansion measurement:

- 360-degree analysis of individual rotor levels

- Analysis of elastic and plastic behavior

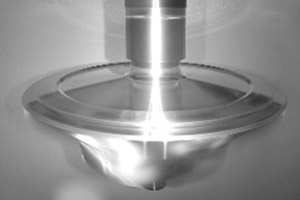

Rotor Burst with High-Speed camera:

- Highspeed-Video during burst tests

Visual Inspection & High-definition video:

- High resolution visual inspections at standstill or during the spin cycle

Unbalance analysis:

- Measurement of the unbalance condition before and after spinning

- Detailed analysis of the changes

- Cause allocation in the rotor design

Plastic deformation analysis:

- Comparative measurement of the geometry before and after the centrifuging process

- Detailed analysis of the plastic deformation

Green Technology - Side by side with your sustainable journey

Elevating your sustainable solutions with our rotor balancing, spin testing and design consulting. Download brochure now!

Test laboratory for balancing technology

We offer our customers a wide range of services in the field of balancing and spin testing, depending on your rotor and your area of application. In our Green Technology Center, we can use the latest technology to offer you innovative analysis options.

Standard-compliant proof quality:

- Traceable to international SI units

- In-house developed, precise reference rotors that, in conjunction with highly precision reference machines (master machines), serve as reference standards for the measurand unbalance

- Based on international standards such as DIN EN ISO 9001, DIN EN 9100, IATF 16949, DIN EN ISO 10012, SAE AS 9100 and VDA 6.1, 6.2 and 6.4

Testing of working standards:

- Test rotors and masses in accordance with ISO 21940-21 or SAE ARP 4162

- Setup and master rotors for balancing machines in serial production

- Other disk- and cylindrical-shaped standards or entire assemblies

- Standardised or self-manufactured standards

- Three performance levels to suit your QM system: laboratory test certificate, works test report and test protocol

Testing and maintenance of machines:

- Inspection of universal balancing machines in accordance with ISO 21940-21 or SAE AS8617: 2020-08 (includes SAE ARP 4048 / 4050 / 5323 / 6217)

- Inspection of balancing machines in individual or batch production

- Inspection of high-speed balancing machines for tasks in accordance with ISO 21940-12 (outside accredited test procedures)

- Inspection of spin testing systems

Our holistic approach

We offer our customers comprehensive support throughout the entire process. From consulting and planning to measurement and testing, we are by your side to ensure that your needs are met comprehensively and effectively.

Spin testing

We perform all necessary work on your rotors for new and further developments or as part of quality assurance.

Prototype testing

Only when a component has been built as a prototype can its strengths and weaknesses become apparent. We analyze rotors and determine how they will behave in real operation.

Test laboratory

Make sure that your balancing and spin testing system meets the required standards. We can help you with this – with a range of customized service packages.

Products

From spin stands to balancing machines for rotors in series production. Our Green Technology product portfolio covers the entire process chain.